SEARCH

BY APPLICATION

Laser Transmission Welding (LTW®)

Laser Transmission Welding has been gaining in popularity as an alternative method of joining plastics in comparison to using traditional methods such as hot plate, vibration, and ultrasonic welding.

LTW can improve the appearance of plastic welded parts by eliminating burns from the surface of welded materials. In addition, the laser beam can be optically controlled via beam diameter, and this method is almost free from distortion caused by heat, making it possible to weld thin plastic parts.

Principal Usage

Colorant for Laser Transmission Welding

Product

Master batch for laser transmission eBIND® LTW® series

Master batch for absorbance control eBIND® ACW® series

eBIND® LTW®

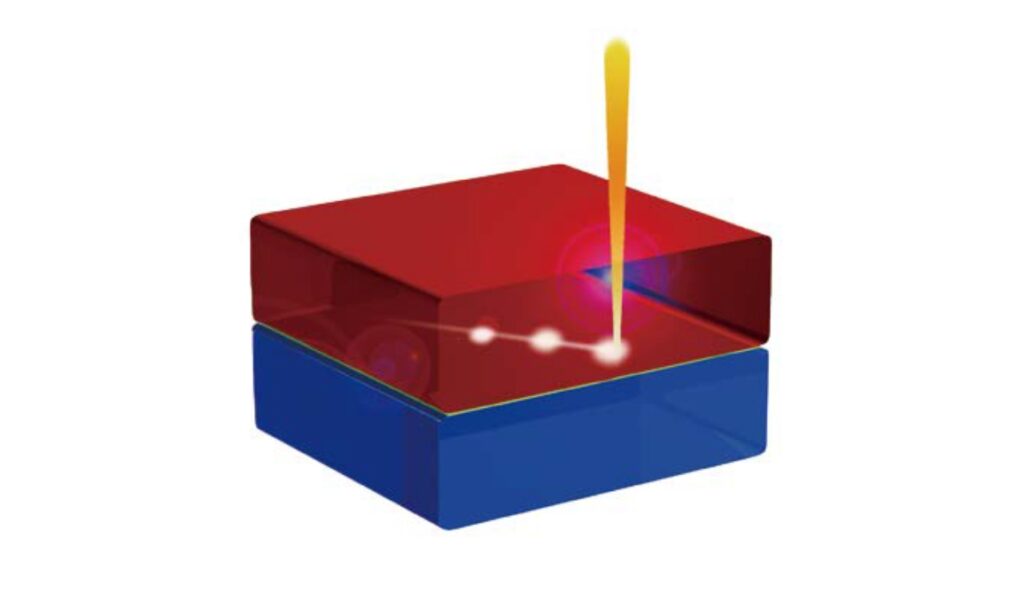

Laser Transmission Welding is a new method in which;

1) The laser beam radiates the two pieces of resin.

2) The laser beam transmits through the “Laser Transmission Material” and changes into heat on the surface or inside of the “Laser Absorption Material”.

3) The heat is conducted from the “Laser Absorption Material”to the “Laser Transmission Material”. As a result, a melting pool is formed.

4) The materials are joined at the interface.

We produce these grades of materials or both transparent and crystalline resins.

| Product name | Color | Information |

|---|---|---|

| eBIND LTW-8701H | Base resin: PA66 Recommended Dilution Ratio 50-fold | |

| eBIND LTW-8601H | Base resin: PA6 Recommended Dilution Ratio 50-fold | |

| eBIND LTW-8904 | Base resin: PBT Recommended Dilution Ratio 50-fold | |

| eBIND LTW-8400C | Base resin: PPS Recommended Dilution Ratio 25-fold | |

| eBIND LTW-8210 | Base resin: AS Recommended Dilution Ratio 25-fold | |

| eBIND LTW-8250 | Base resin: PS Recommended Dilution Ratio 25-fold | |

| eBIND LTW-8310 | Base resin: PC Recommended Dilution Ratio 25-fold |

eBIND® ACW®

To put it briefly, it is a method of laser welding between resin partsof the same type to control the balance between laser transmission andlaser absorption by resin material. In other words, this is absorbancecontrol welding and we call it “the ACW® method.”

| Product name | Color | Information |

|---|---|---|

| eBIND ACW-9871 | Base resin: PA66 Recommended Dilution Ratio 40-fold | |

| eBIND ACW-9861 | Base resin: PA6 Recommended Dilution Ratio 20-fold | |

| eBIND ACW-9025 | Base resin: AS Recommended Dilution Ratio 25-fold |